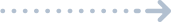

Product Introduction

Jaw Crusher is suitable for primary and secondary crusher for material with compression strength less than 320MPA.Jaw Crusher is of crushing ratio, capacity, final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc.It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

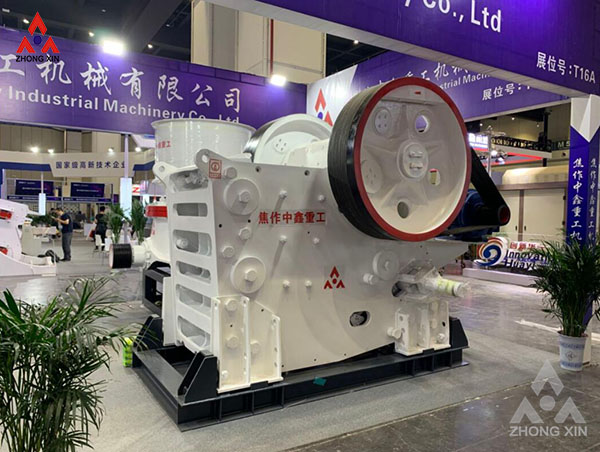

Product Advantages

Fully hydraulically operated, it is easy to use.

It is easily automated, significantly improving its reliability and service life.

Fully hydraulically operated, it is easy to use.

It is easily automated, significantly improving its reliability and service life.

Fully hydraulically operated, it is easy to use.

It is easily automated, significantly improving its reliability and service life.

Fully hydraulically operated, it is easy to use.

It is easily automated, significantly improving its reliability and service life.

Product Photos

Specification

Model | ZXC80 | ZXC96 | ZXC106 | ZXC116 | ZXC110 | ZXC120 | ZXC125 | ZXC140 | ZXC145 | ZXC150 | ZXC160 | ZXC200 | ||

| Width of feed opening (mm) | 800 | 930 | 1060 | 1150 | 1100 | 1200 | 1250 | 1400 | 1400 | 1500 | 1600 | 2000 | ||

| Deepth of feed opening(mm) | 510 | 580 | 700 | 800 | 850 | 870 | 950 | 1070 | 1100 | 1200 | 1200 | 1500 | ||

| power (kw) | 75 | 90 | 110 | 132 | 160 | 160 | 160 | 200 | 200 | 250 | 250 | 400 | ||

| Eccentric shaft speed(rpm) | 350 | 330 | 280 | 260 | 230 | 230 | 220 | 220 | 220 | 220 | 220 | 200 | ||

| Weight(KG) | 8060 | 11353 | 18700 | 19390 | 26150 | 28160 | 39239 | 47120 | 57723 | 74000 | 79993 | 121500 | ||

| Output size (mm) | The tight side discharge opening | (t/h) | ||||||||||||

| 0-30 | 20 | |||||||||||||

| 0-35 | 25 | |||||||||||||

| 0-45 | 30 | |||||||||||||

| 0-60 | 40 | 65-85 | ||||||||||||

| 0-75 | 50 | 80-95 | ||||||||||||

| 0-90 | 60 | 95-125 | 120-155 | |||||||||||

| 0-105 | 70 | 115-150 | 140-180 | 155-200 | 170-220 | 190-250 | 205-265 | |||||||

| 0-120 | 80 | 130-170 | 160-210 | 175-230 | 190-250 | 210-275 | 225-290 | |||||||

| 0-135 | 90 | 150-195 | 180-235 | 200-260 | 215-280 | 235-305 | 250-320 | |||||||

| 0-150 | 100 | 165-215 | 200-260 | 220-290 | 240-310 | 255-330 | 270-345 | 290-380 | ||||||

| 0-185 | 125 | 210-275 | 250-325 | 280-365 | 295-385 | 310-405 | 325-420 | 350-455 | 385-500 | 400-520 | ||||

| 0-225 | 150 | 250-325 | 300-390 | 335-435 | 350-455 | 370-480 | 385-495 | 410-535 | 455-590 | 470-610 | 478-620 | 520-675 | ||

| 0-260 | 175 | 290-380 | 350-455 | 390-510 | 405-525 | 425-550 | 440-565 | 470-610 | 520-675 | 540-700 | 548-710 | 595-775 | 760-990 | |

| 0-300 | 200 | 445-580 | 460-600 | 480-625 | 495-640 | 530-690 | 590-765 | 610-795 | 618-805 | 675-880 | 855-1110 | |||

| 0-340 | 225 | 590-770 | 655-850 | 680-885 | 688-895 | 750-975 | 945-1230 | |||||||

| 0-375 | 250 | 650-845 | 725-945 | 750-975 | 758-980 | 825-1070 | 1040-1350 | |||||||

| 0-410 | 275 | 820-1070 | 828-1075 | 900-1170 | 1130-1470 | |||||||||

| 0-450 | 300 | 898-1160 | 980-1275 | 1225-1590 | ||||||||||

WhatsApp

WhatsApp Wechat

Wechat